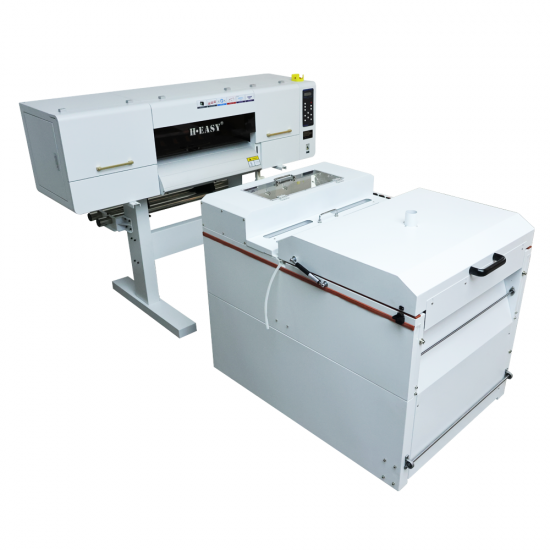

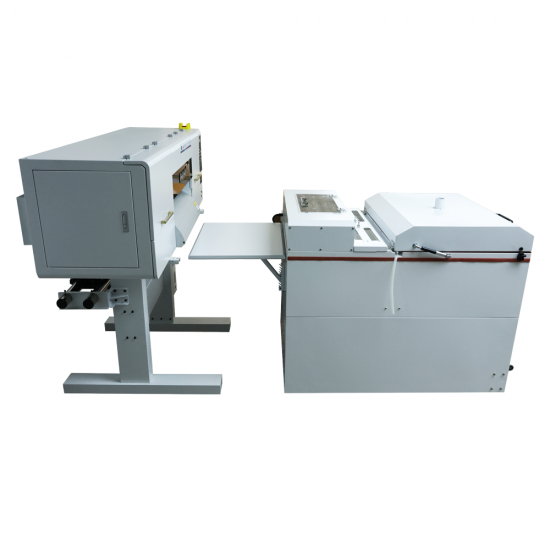

HY-702 70cm DTF printer

- Stock: 10000

- Model: HY-702

- Weight: 250.00kg

- SKU: 03.14.01.001.001

70cm DTF printer

- Epson-i3200A1 print head.

- Auto-lift cleaning station.

- Large capacity bulk ink system.

- Adjustable head height

- Wide anti-static pinch roller.

- Import mute rails, all aluminum beams, to ensure high stability and high-quality output.

|

Model |

HY-702 |

|

|

Print head |

Double i3200A1 |

|

|

Print Mode |

4C+W |

|

|

Print width |

600mm |

|

|

Print speed |

4 Pass |

17m/h |

|

6 Pass |

12m/h |

|

|

Print resolution |

1440 DPI |

|

|

Print materials |

PP/PET film. |

|

|

Print height |

≤5mm |

|

|

Ink type |

Special DTF ink |

|

|

Curing system |

Hosonsoft |

|

|

RIP Software |

Photoprint/RIIN |

|

|

Data connection |

USB3.0 |

|

|

Input power |

220VAC(±10%) single phase ,50/61 HZ |

|

|

Power |

700W |

|

|

package size/N W |

1.82m(L)*0.87m(W)*0.75m(H)

|

|

What's the DTF Printing Technology?

DTF Printing Technology stands for Direct to Film printing.

It's a modern digital printing method widely used in the textile and apparel industries for transferring full-color designs onto various fabrics, especially cotton, polyester, and blends.

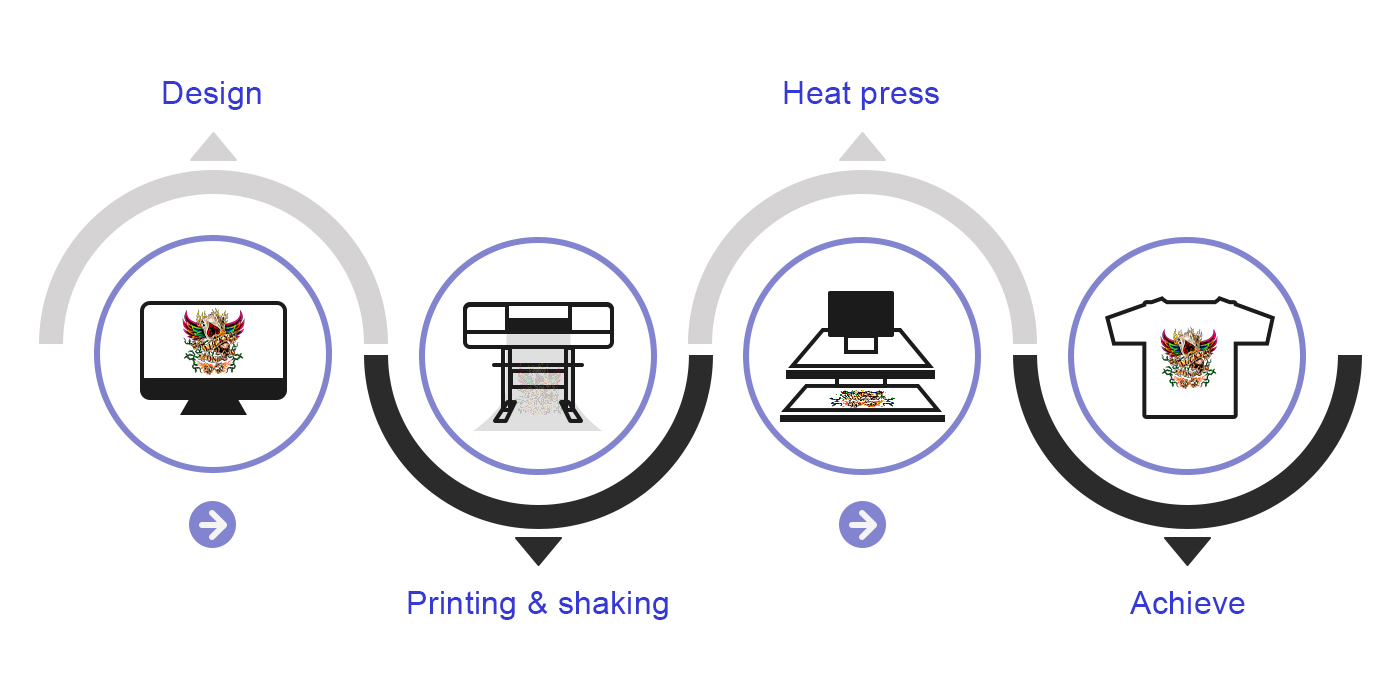

How DTF Printing Works

1. Design Creation

The process begins by creating the desired artwork digitally using graphic design software like Photoshop or Illustrator.

2. Print on PET Film

The design is printed in mirror image onto a special PET (polyethylene terephthalate) film using a DTF printer and pigment-based inks (typically CMYK + white).

3. Apply Hot Melt Powder

A hot-melt adhesive powder is applied to the printed film while the ink is still wet. The powder sticks only to the inked areas.

4. Curing

The film with the adhesive powder is passed through a curing oven or heat press to melt the powder, forming a sticky layer.

5. Transfer to Fabric

The prepared film is placed on the target fabric, and a heat press (around 160–170°C for \~15 seconds) is used to transfer the design.

6. Cold Peel

After pressing, the film is allowed to cool and then peeled off, leaving a vibrant design on the fabric.

Advantages of HY702 DTF Printer

Versatility: Works on cotton, polyester, blends, denim, leather, and more.

No pre-treatment needed(unlike DTG – Direct to Garment).

Bright, vibrant colors with good wash durability.

Low cost for small-batch production and personalized printing.

Soft and stretchable feel, especially with high-quality powders and films.

Technology Advantage:

Industrial-grade piezo printheads that support high-precision output.

1440DPI.

4Pass, 17m/h; 6Pass, 12m/h.

Support simultaneous output of white ink and color ink for dark/light materials.

Cost advantage:

Low cost of consumables, more economical compared with traditional screen printing/heat transfer printing.

No plate making, flexible for small batch production.

Ease of use:

Intelligent calibration system, friendly operation interface.

Support one-touch maintenance, automatic cleaning printhead.

HY702 DTF Printer Printing Process

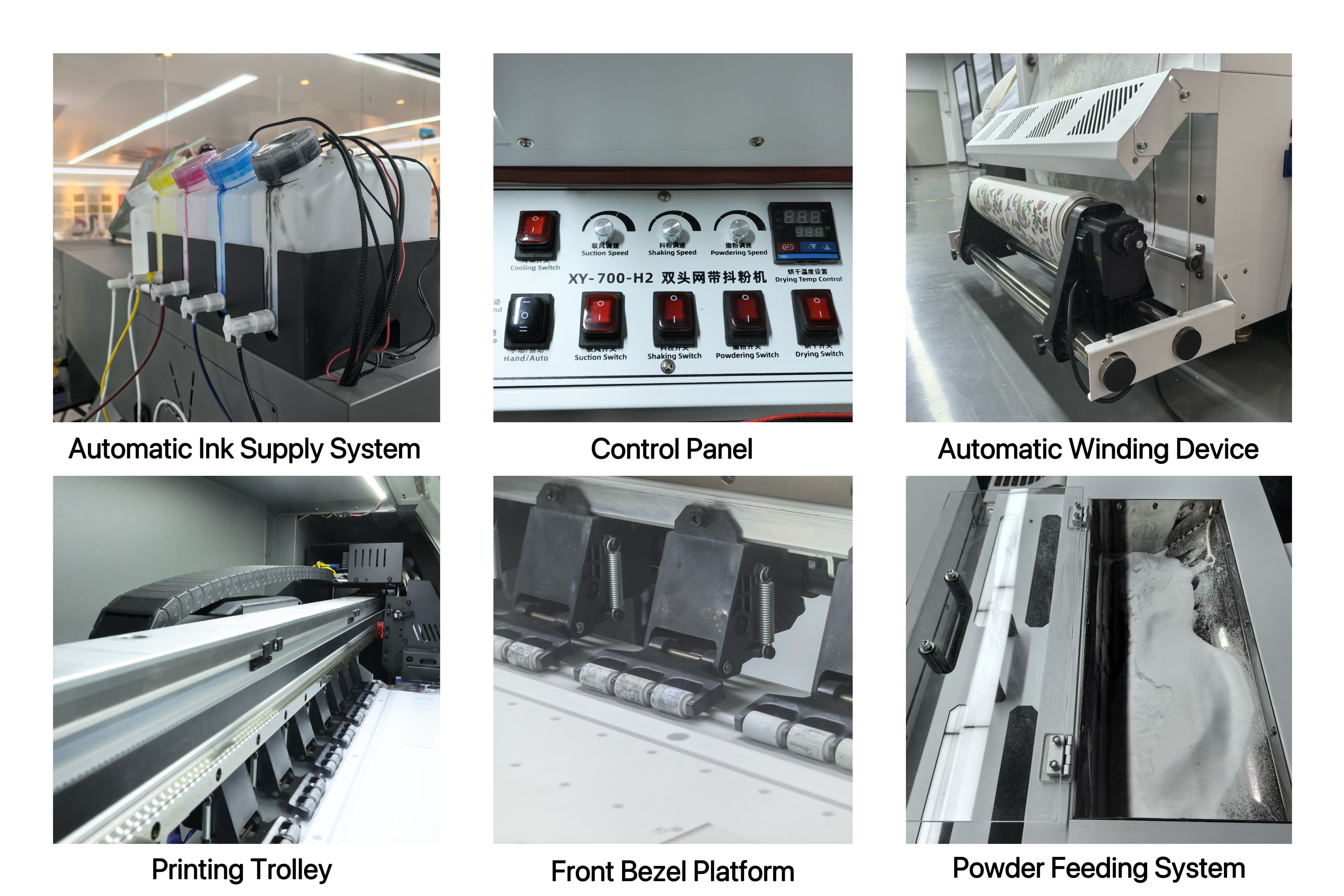

HY702 DTF Printer Details

15 Reasons Why the HY702 DTF Printer is a Great Addition for Your Business

1. Powerful original printing system, ensures printing stability

2. Fully automatic print output, one person can operate multiple units.

3. Optional 4-8 color printing, compatible with various print effects

4. Continuous lnk System avoids frequent ink refills or downtime because of the lack of ink and enabling low-cost production.

5. Ink automatic circulation, white ink stirring function to ensure ink fluidity, ink shortage alarm system.

6. Powder recycling system to reduce production costs.

7. Matte, glossy, fluorescent print effect that can be switched at will, a multi-purpose model.

8. Provide Al voice control system to operate and maintain the machine.

9. Optional 1-4 heads, automatic switch printing speed.

10. Automatic smoke exhaust that provides a smoke-free printing environment.

11. Adopts the SAl PhotoPrint software that's easy to use.

12. Provide video tutorials, easy to operate.

13. Senior engineers available, offering a lifetime maintenance guarantee

14. Paid local services are available. No worry about installation and after-service

15. Provide free operator training services till the point you know how to operate it on your own.

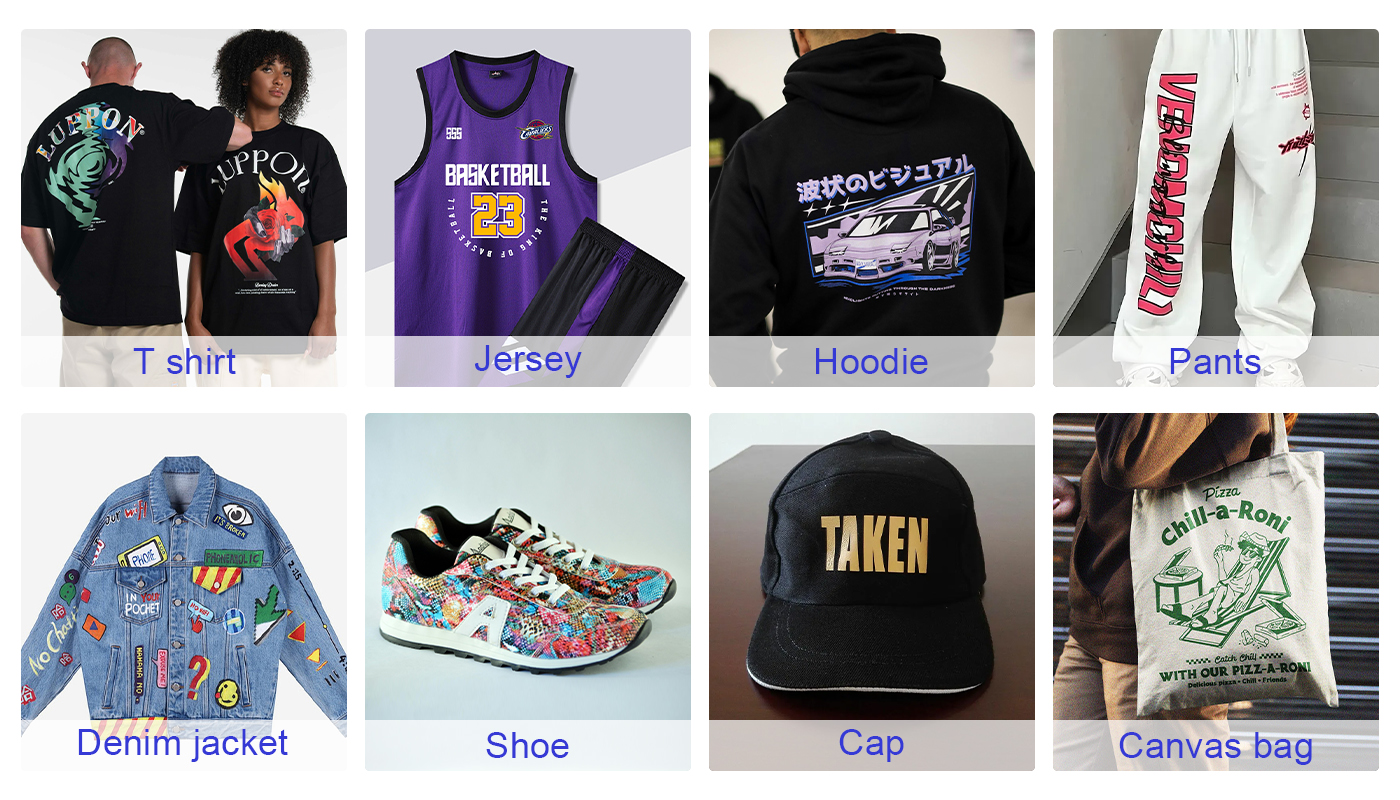

HY702 DTF Printer Application

If you're looking for a DTF printing solution that combines high speed, precision, and stability, the HY702DTF is your ideal choice. Equipped with dual printheads, it delivers fast printing and vibrant colors, perfect for handling large orders with ease. Whether it's for custom apparel, team T-shirts, or personalized designs, the HY702DTF provides sharp, long-lasting, and expressive image output, significantly boosting both production efficiency and customer satisfaction.

Frequently Asked Questions (FAQ)

What is the cost of consumables?

Does it require a special environment (temperature and humidity requirements)?

Difficulty and frequency of maintenance?

What design software is supported?

(For more information, please contact us)